Topic outline

-

Ports play a decisive role in the EU’s external and internal trade, as about 74% of imports and exports and 37% of exchanges go through ports. Although ports and especially Deep Sea Shipping (DSS) ports are integral nodes within multimodal logistic flows, Short Sea Shipping (SSS) and inland waterways are not so well integrated.

The aim of MOSES project is to enhance the SSS component of the European supply chain by addressing the vulnerabilities and strains related to the operation of large containerships. A two-fold strategy will be followed, in order to reduce the total time to berth for TEN-T Hub Ports and to stimulate the use of SSS feeder services to small ports that have limited or no infrastructure.

The above-mentioned scope of MOSES project will be reached through the implementation of the following innovations:

o For the SSS leg an innovative, hybrid electric feeder vessel including robotic cargo handling system (MOSES feeder).

o For DSS ports the adoption of an autonomous vessel maneuvering and docking scheme (MOSES AutoDock).

o A digital collaboration and matchmaking platform (MOSES platform)MOSES is an ambitious project that bears significant innovation potential in the context of European SSS uptake. Its innovation potential covers both vessel design aspects as well as software tools and accompanying governance models to improve related logistics processes.

The key objectives of MOSES project are organised in three pillars:

Technical (TO)

TO1: Design of an innovative, hybrid electric feeder vessel outfitted with a robotic container-handling system.

TO2: Development of an automated system for the reduction of maneuvering and docking time for DSS ports.

TO3: Development and promotion of the MOSES matchmaking platform to foster SSS.Societal (SO)

SO1: Reduction of the environmental footprint for SSS services and port areas compared to other modes.

SO2: Improvement of the efficiency and end-to-end delivery times of SSS mode.Market (MO)

MO1: Development and upscaling of concrete business cases for SSS.

MO2: Promotion of the economic development of small ports with minimal investment.MOSES Concept

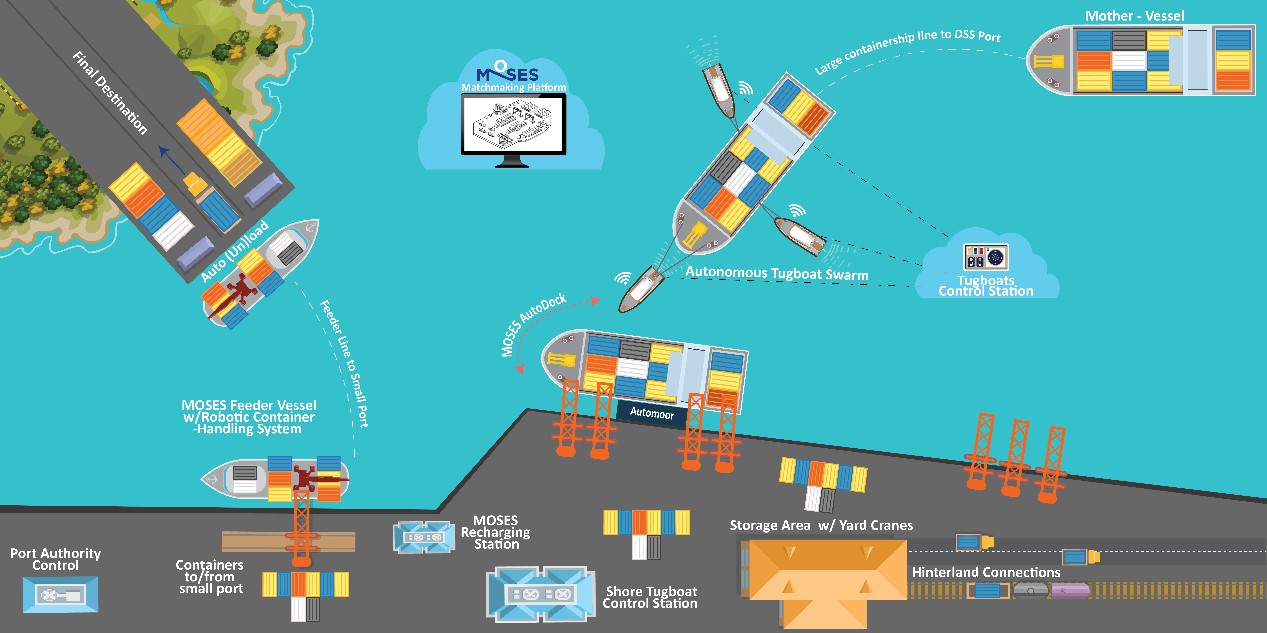

A large containership (mother-vessel) at the DSS port is assisted from the MOSES AutoDock, a combined intelligent mega-system consisting of the MOSES Autonomous tugboat swarm for maneuvering and the MOSES adapted AutoMoor system. The automated maneuvering and docking process are monitored through the MOSES Autonomous Tugboat Control Station. Containers to be shipped to destinations near small ports are stacked by existing port equipment near dedicated berths of the DSS port and loaded on the MOSES Innovative Feeder Vessel, which is equipped with the MOSES Robotic Container-Handling System that provides (semi-) autonomous (un)loading of the feeder.

The hybrid electric feeder, while berthed at the DSS port, may use the MOSES Recharging Station, which is an automated shore-based power system. The laden MOSES Feeder proceeds to the small port where it automatically unloads its containers either at the quay or directly on trucks bound for the destination. As a result, ports with minimal or no available infrastructure may be effectively integrated in the container supply chain.

The MOSES concept is supported by the MOSES Matchmaking Platform to handle effectively changing freight flows, to increase the cost-effectiveness of partial cargo loads, and to boost last-mile/just-in-time connections among transport modes and backhaul traffic.

List and short description of relevant pilots/living labs or test beds demonstrations.

Three pilot demonstrations will be conducted during MOSES duration.

Pilot 1: AutoDock

This pilot aims to showcase the automated maneuvering, docking, and mooring scheme for large ports proposed by MOSES. This is achieved by demonstrating the way that a swarm of autonomous tugboats may intelligently cooperate to maneuver a large container ship and direct it into an available berth at the port and the way that tugboats may collaborate with an automated mooring system that will efficiently complete the process.

The model testing physical scenario, will be conducted according to the local environmental conditions prevailing at the time of the demonstration. In addition, the demonstration aims at appropriately addressing a wide range of operational scenarios to simulate a use case as realistically as possible. AutoDock pilot will be carried out at the physical area surrounding Faaborg harbour in Denmark, where TUCO maintains their facilities.

Pilot 2: Innovative Feeder Vessel

The objective of this pilot is to showcase the innovative characteristics of the MOSES feeder vessel by demonstrating its seakeeping and energy performance capabilities. This activity will include testing a scaled ship model for one – out of the 3 total – vessel designs conceptualized within MOSES. The ship models will be constructed by MARIN at their facilities and the design properties include service speed, maneuvering and seakeeping performance in various operational conditions and scenarios. Furthermore, this demonstration may involve how the MOSES innovative feeder may keep track and be used for autonomous mooring taking into consideration the potential for fully autonomous operation in the future. An additional option for this demonstration is to include testing of a sustainable propulsion solution depending on the concept design that will be chosen. Innovative feeder vessel pilot will be conducted at MARIN’s Seakeeping and Maneuvering Basin (SMB) in the Netherlands.

Pilot 3: Robotic Container Handling System

This pilot demonstration aims to showcase the (semi)autonomous operation for (un)loading containers from the MOSES innovative feeder with the Robotic Container-Handling System that will be developed. This will be accomplished by demonstrating the autonomous container handling capability of the system, the shared control between the human (remote) driver and the robotic crane system. Intervention options for the remote operator through the remote supervisory Shore Control Station (SCS) will be also demonstrated. This pilot demonstration will be conducted at the MacGregor test facility in Örnsköldsvik (Sweden), where the crane itself will be mounted on the shore (instead of onboard a vessel) for cost-efficiency reasons.

For subscribing to our newsletter please use the following link: http://eepurl.com/hbM7Sbwww.moses-h2020.eu

-

Forum

-